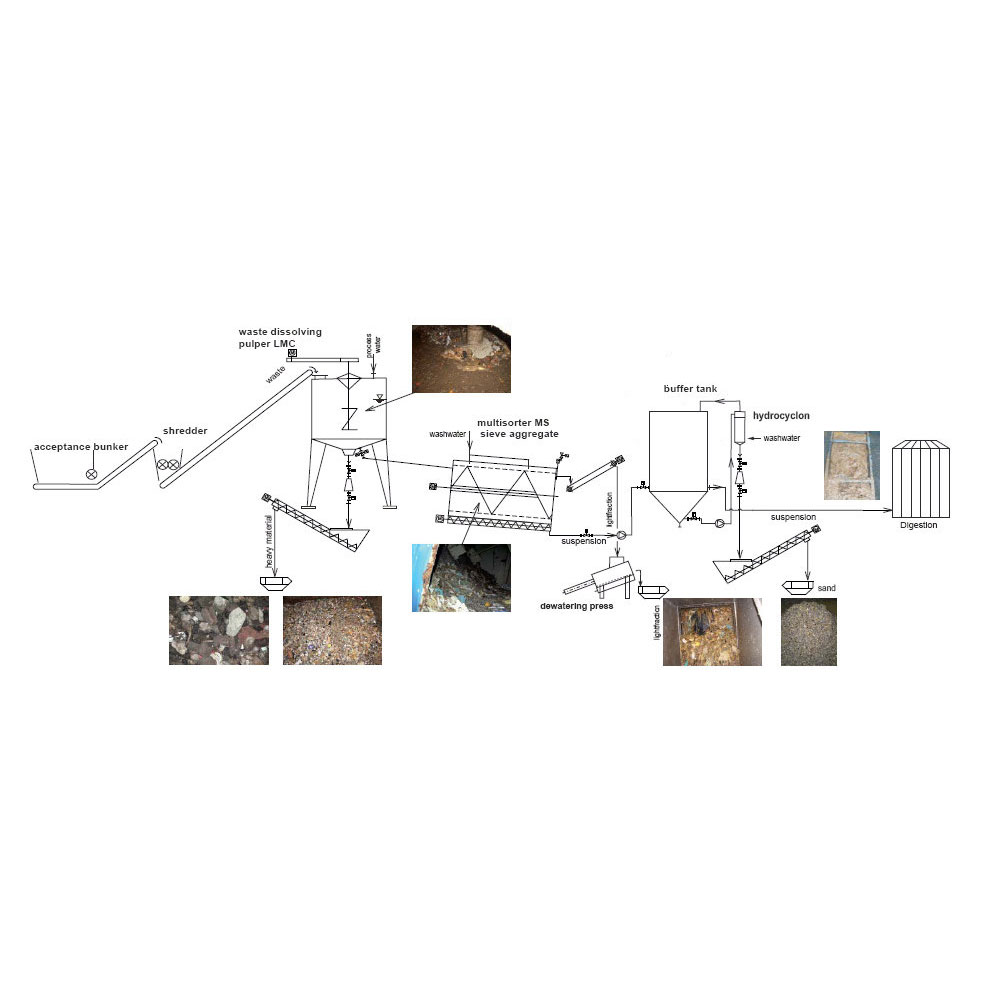

Bio-mechanical Wet Treatment Plant

for biowaste, foodwaste and household waste

Process technology for various organic waste for the wet fermentation

By the Lohse wet treatment technology with the help of „pulper-systems“ and sieving, a pumpable and well fermentable suspension is obtained with very low content of impurities.

Procedure

First, in the waste pulper, the organic waste is dissolved by strong agitation while the heavy materials are separated.

In the downstream sieving device is the careful separation of another impurities from suspension. The suspension thus obtained can be pressed in a following digesting system.

The Lohse waste pulper and the following sieving device are manufactured in different sizes, according to the quantity of waste up to approx. 12 tons per hour.

- Optimal separation of impurities by a wet liquid treatment

- low load in the suspension with impurities

low formation of floating roofs

- low load in the suspension with impurities

- Separation of impurities at the beginning of the process

- protection the following pumps and aggregates

low pollution of digestable suspension

- protection the following pumps and aggregates

- It can be processed organic waste with drymatter content (DM) of about approx. 15% DM (e.g. food waste) to about approx. 50% DM (e.g. gassilage, manure, pre-sorted houshold waste)

- By the dissolving process in the waste-pulper the organic waste components are disolved very well and the surface increases, the gas yield is higher.

- Grain size of waste < 150mm in the waste-pulper is enough, so no expensive shredding is necessary.

- stabel construction and special materials for toughest operating

- low interference, low maintenance

- low running costs by few wearing parts

- closed system, therefore minimizing smell emissions

- fully automatic operation possible

- advanced and tested technology with more than 25 years experience

Examples

Waste dissolving

Dewatering press

Buffer tank