Rejector

To purify and disintegrate the raw suspension

Application

The rejector is used as a sieving machine and serves to purify and disintegrate the raw suspension from waste pulping units or storage containers.

Advantages

- foreign bodies (cutlery, steel parts, stones, textiles, plastic film etc) remain in the container and are not forced through the sieve.

- less cost for wearing parts.

- lower energy consumption

- simple adaptation to various types of waste

Construction and function

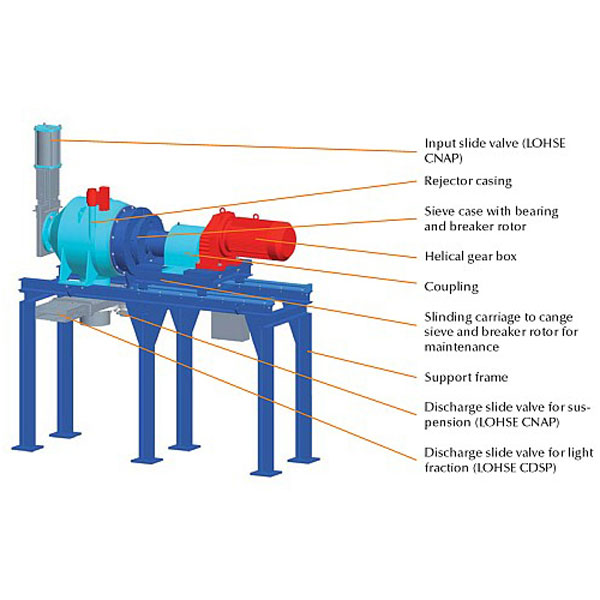

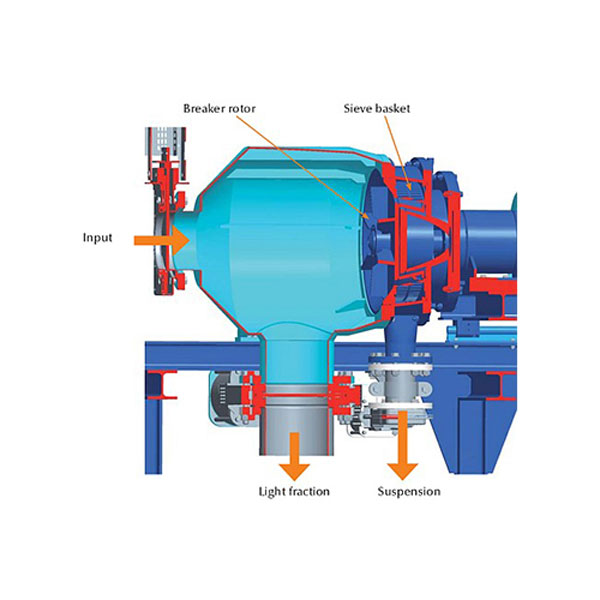

The raw suspension is intermittently fed to the centre of the rejector. The rejector is a closed cylindrical container with a central disintegrator wheel to which a sieving unit is flange-mounted.

The disintegrator wheel installed in the container causes a pronounced rotational movement, which causes a disintegration of the raw suspension. The raw suspension which has been thus disintegrated flows through the sieve unit and is extracted by means of an upstream pump. Particles which are larger than the perforations of the sieve remain in the container and are held back.

After a time, which can be adjusted, the foreign particles in the container become more concentrated. By the addition of flushing water, the fraction of foreign particles remaining in the container (material to be sieved) is washed out.

After this, by opening a slide valve which is attached to the base of the container by means of a flange, the remaining contents in the container (the foreign particles) are removed from the rejector. Once the material to be sieved has been removed from the rejector, a new cycle begins.

Main components using the example of type F04

Function using the example of type F04

- Mailing of the raw suspension coming from the pulper or acceptance tank

- Separation the light fraction from raw suspension (plastic, wood, textiles) and other rest impurities (bones, metal, stones)

- Particlesize in accordiance with hygienisation rules, stock preparation

Technical data

| Type | F04 | F010 | |

| Throughput paper pulp TS 4–6% | m3/h | 18 | 48 |

| Throughput leftover TS 10–18% | m3/h | 3 | 10 |

| Useable volume tank | dm³ | 180 | 1000 |

| Tank diameter | mm | 650 | 1200 |

| Impeller diameter | mm | 410 | 950 |

| Intake nozzle | mm | DN 125 | DN 250 |

| Accepted stock nozzle | mm | DN 100 | DN 200 |

| Reject discharge light and heavy fraction | mm | DN 250 | DN 500 |

| Flush water nozzle | mm | DN 50 | DN 50 |

| Speed impeller | 1/min | 555 | 322 at 50 Hz |

| AC motor | kW | 22/30 | 45 |

| Material tank | 14571 | 14571 | |

| Material support, frame (not in touch with medium) | S235JR painted | St 37-2 painted | |

| Operating weight (filled) | kg | approx. 1700 | approx. 4000 |

| Tare weight | kg | approx. 1400 | approx. 3100 |

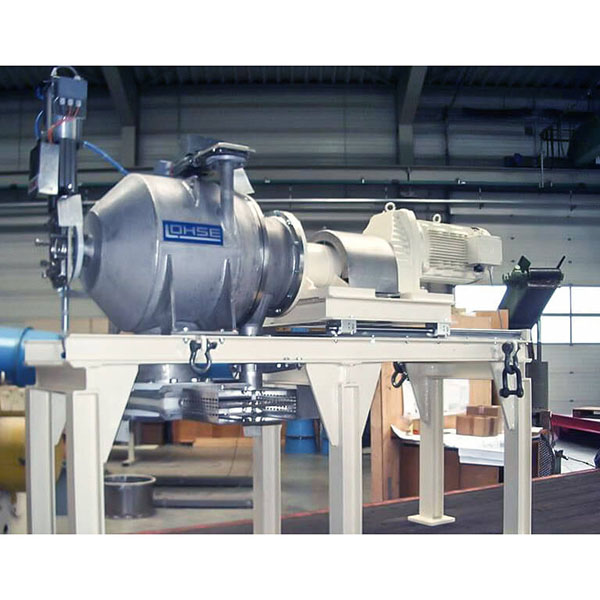

Examples