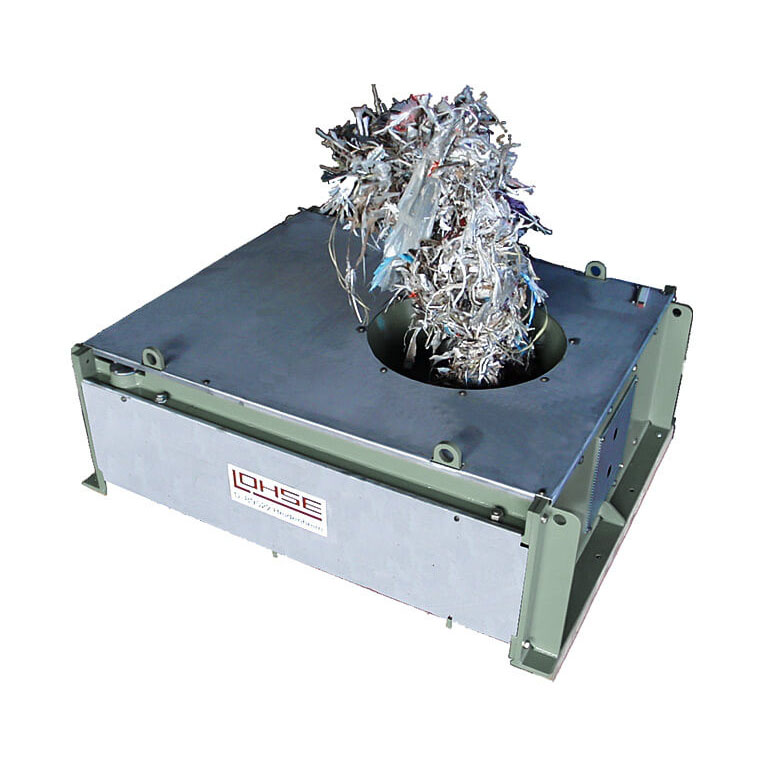

Rope Cutters

Aggregates and individual components for Waste Paper Pulpers

The suspension that rotates on the pulping process in the waste paper pulper spins the contrary material that came in with the waste paper, such as, e.g. wires, films, plastic and insoluble paper, into a rope. This rope is drawn out of the waste paper pulper with a rope winch. The rope winch is driven with a suitably variable interval switching. Depending on the amount of contrary material in the waste paper to be processed, and on the size of the pulper, endless ropes with a diameter of between 150 mm and 500 mm are formed. For disposal purposes these ropes must be cut into transportable pieces. This is done with a Lohse rope cutter, which is installed behind the rope winch in such way that the rope emerging from the winch is led without force via a funnel into the cutting opening. Lengths very between 300 mm and 3000 mm, depending on customers‘ wishes.

Installation and function

The rope cutter consists of two cutter bars with four integrated reversing scissor blades, which are moved in the opposite direction to the middle of the scissors by means of a hydraulic cylinder. The rope is cut through without interrupting production and without an increased risk of accident.

The hydraulic cylinders are operated and the cutting procedure is controlled with an external hydraulic unit coordinated to the rope cutter. Manual or automatic mode can be selected with a preselection switch. In manual mode the cutting procedure can be initiated at any time by pressing a switch at the switchgear cabinet. Automatic mode is possible if the controller is integrated correspondingly with the waste paper pulper operations. If the waste paper pulper is switched off during a cutting procedure, this is carried out and the cutter bar then returns to the starting position

Lohse rope cutters DW 700 – for a rope diameter up to 500 mm

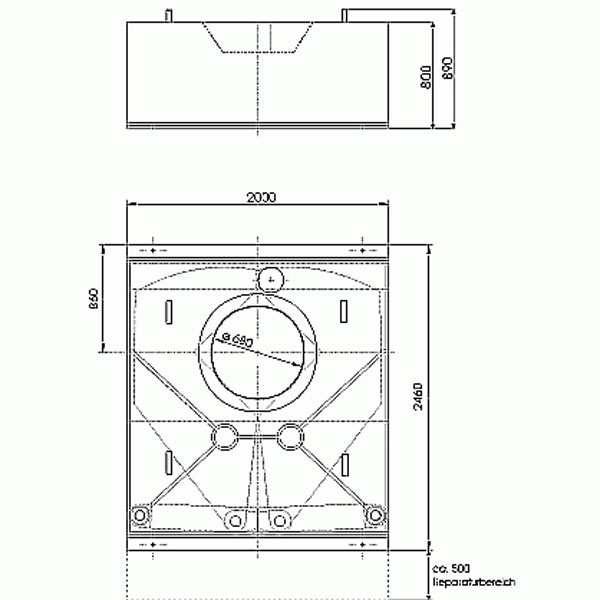

Technical drawing

Technical data

| size: | DW 700 |

| cut opening: | 700 x 700 mm |

| hopper opening: | Ø680 mm |

| cutting force: | ca. 500 kN |

| cutting time: | ca. 130 sec. |

| cutting intervals: * | adjusable by timer |

| hydraulic driver motor: | 5,5 kW |

| hydraulic pressure max.: | 250 bar |

| width: | 2000 mm |

| height: | 890 mm |

| length: | 2460 mm |

| weight: | 4800 kg |

* depending on ragger speed